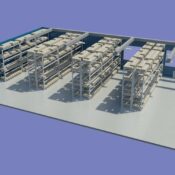

In the heart of Dammam, where the coastal humidity meets intense desert heat, maintaining stable conditions for pharmaceutical storage is both a science and a necessity. For companies dealing with vaccines, biologics, and temperature-sensitive drugs, even minor fluctuations in temperature can impact product integrity and patient safety. This is where the temperature mapping study becomes an essential quality assurance process — ensuring that cold rooms perform reliably under all conditions.

At Eximia360 (www.eximia360.com), we provide expert temperature mapping studies across Saudi Arabia, including Jeddah, Dammam, and Riyadh, helping pharmaceutical facilities comply with stringent regulations while optimizing performance. Based on our experience, here are ten key insights gained from conducting temperature mapping in Dammam’s pharma cold rooms.

1. Uniform Cooling is Rare Without Mapping

Even in advanced cold rooms, temperature variation can occur due to air circulation patterns, door openings, or equipment placement. Through temperature mapping studies, we’ve identified “hot spots” near doorways and “cold zones” close to air outlets — areas that could compromise medicine stability if unnoticed.

2. Sensor Placement Determines Accuracy

Precision in sensor distribution is vital. Eximia360 ensures sensors are strategically placed throughout the cold room — at corners, midpoints, and near air vents — to capture the complete thermal profile. This approach provides a true representation of temperature variations, not just localized readings.

3. External Climate Influences Internal Stability

In Dammam, high ambient temperatures and humidity can challenge even the most insulated facilities. Our temperature mapping studies consistently show how external conditions influence internal temperatures, especially during peak summer months. This data helps adjust cooling strategies for long-term stability.

4. Door Operations Are a Hidden Risk

Every time a cold room door opens, warm air enters and disrupts temperature equilibrium. By analyzing mapping data, Eximia360 helps clients identify how long it takes for rooms to return to the validated range, ensuring Standard Operating Procedures (SOPs) align with real-world conditions.

5. Power Fluctuations Affect Temperature Consistency

Power instability can lead to unnoticed temperature deviations. Mapping data allows facilities to plan for power interruptions and implement reliable backup systems to protect sensitive pharmaceutical products.

6. Air Circulation Design is a Critical Factor

Our temperature mapping studies reveal that uneven airflow is a major cause of non-uniform temperatures. Eximia360 provides recommendations to redesign air circulation or reposition diffusers, ensuring consistent conditions across the cold room.

7. Equipment Load Testing Matters

Cold rooms often perform differently when empty versus fully loaded. That’s why Eximia360 conducts temperature mapping studies under both conditions — to simulate real operational performance and validate temperature consistency across all load scenarios.

8. Continuous Monitoring Improves Compliance

Regulatory bodies such as the World Health Organization (WHO) and Good Distribution Practice (GDP) guidelines emphasize continuous monitoring. Temperature mapping forms the foundation for automated data-logging systems, ensuring facilities stay audit-ready at all times.

9. Mapping Frequency Should Match Risk Level

In Dammam’s pharma sector, temperature mapping studies are recommended at least annually — or whenever layout changes occur, such as relocation or new equipment installation. This periodic validation ensures the environment remains within safe temperature ranges year-round.

10. Data-Driven Optimization Builds Trust

Beyond compliance, consistent temperature mapping reflects a company’s commitment to quality. By analyzing historical mapping data, pharmaceutical businesses can optimize operations, reduce wastage, and build stronger trust with healthcare providers and consumers.

Conclusion: Mapping the Future of Pharma Quality

In Dammam and across Saudi Arabia, pharmaceutical integrity depends on more than cooling systems — it relies on precision, validation, and proactive quality management. Temperature mapping studies provide the critical insights needed to maintain control, ensure compliance, and safeguard every product stored or transported.

At Eximia360, our expert engineers conduct end-to-end temperature mapping studies — from sensor installation and data collection to analysis and report generation — ensuring your facility meets both local and international standards.

If your pharma operations are based in Riyadh, Dammam, or Jeddah, now is the time to partner with Eximia360 to ensure your cold rooms deliver uncompromised performance and product safety.

Visit us at www.Eximia360.com to learn how we’re transforming temperature mapping into a smarter, data-driven quality practice for Saudi Arabia’s pharmaceutical industry.