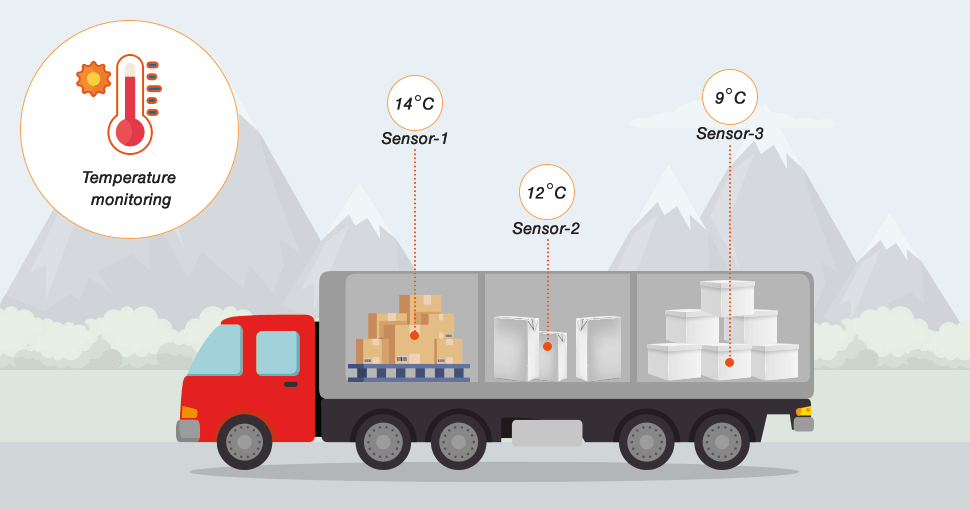

Maintaining consistent temperatures during transportation is one of the biggest challenges in the logistics of pharmaceuticals, food, and other temperature-sensitive products. In Saudi Arabia, where extreme weather conditions prevail, temperature mapping studies have become vital for ensuring the reliability and safety of cold chain logistics. Eximia360, a trusted leader in temperature mapping services across Saudi Arabia, Jeddah, Dammam, and Riyadh, specializes in providing end-to-end solutions for truck-based temperature mapping to ensure regulatory compliance and product integrity. Learn more at www.Eximia360.com.

Below are 9 essential steps for conducting an effective truck-based temperature mapping study that guarantees optimal control and accuracy.

1. Define the Purpose and Scope

Before starting the temperature mapping study, it’s crucial to define the objectives—whether it’s for pharmaceuticals, food products, or sensitive chemicals. Eximia360 begins by identifying the required temperature ranges and determining the operational conditions under which the study will be conducted, ensuring compliance with international standards like WHO, GDP, and ISO.

2. Select the Right Data Loggers

The accuracy of any temperature mapping study depends heavily on the choice of sensors and data loggers. Eximia360 uses advanced wireless data loggers capable of recording temperature and humidity in real time, providing precise insights even under challenging Saudi Arabian climate conditions.

3. Identify Critical Locations in the Truck

Temperature fluctuations often occur in specific parts of a vehicle, such as near doors or cooling units. The team at Eximia360 identifies these critical points to ensure data loggers are strategically placed to capture the full temperature profile of the truck during transport.

4. Conduct Calibration Verification

Before deployment, all sensors and data loggers must be calibrated according to traceable standards. Eximia360 ensures every device used in the temperature mapping study is accurately calibrated, eliminating any risk of measurement errors that could compromise product quality.

5. Perform an Empty Truck Trial

An initial mapping trial with an empty vehicle helps establish the baseline temperature performance. Eximia360 performs this step to assess airflow patterns, insulation effectiveness, and the efficiency of the cooling unit under realistic operating conditions.

6. Run a Loaded Mapping Study

After the empty trial, a fully loaded truck study is conducted using actual or simulated products. This helps Eximia360 identify how load density, packaging, and product placement affect temperature uniformity during transportation.

7. Analyze Data and Identify Hot/Cold Spots

Once the data is collected, Eximia360’s experts analyze it using specialized software to identify hot and cold zones within the truck. These insights are crucial for optimizing loading practices and improving cooling system efficiency.

8. Validate and Document Results

Temperature mapping studies must be documented in compliance with regulatory standards. Eximia360 prepares detailed validation reports that include sensor placement diagrams, recorded data, and analysis results—ensuring full traceability and compliance with industry guidelines.

9. Implement Continuous Monitoring

Temperature mapping is not a one-time process. Eximia360 recommends continuous monitoring solutions for clients in Riyadh, Dammam, and Jeddah to ensure long-term temperature stability and regulatory adherence. Real-time alerts and analytics enable immediate corrective actions in case of temperature deviations.

Conclusion

Truck-based temperature mapping is essential to protect sensitive goods during transport, especially in the demanding climate of Saudi Arabia. Eximia360 combines expertise, advanced technology, and strict validation methods to deliver reliable temperature mapping services that ensure compliance and peace of mind. For trusted temperature mapping studies across Saudi Arabia, Jeddah, Dammam, and Riyadh, visit www.Eximia360.com.