In today’s global supply chain, where sensitive goods like pharmaceuticals, vaccines, perishable foods, and chemicals must be transported and stored under strict temperature conditions, cold chain logistics plays a vital role. Ensuring that temperature-sensitive products remain within defined limits throughout the entire journey—from production to delivery—is critical. One of the most effective tools for ensuring this reliability is Temperature Mapping.

At Eximia360, we specialize in providing professional Temperature Mapping study services across Saudi Arabia, especially in key cities like Jeddah, Dammam, and Riyadh. Our goal is to help businesses optimize their cold chain operations, maintain regulatory compliance, and reduce product losses. Learn more about our services at www.eximia360.com.

What is Temperature Mapping?

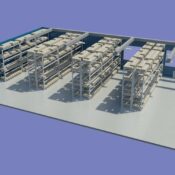

Temperature Mapping is the process of measuring and recording temperature variations in storage and transport environments over a specific period. It helps identify hot and cold zones, temperature fluctuations during operations, and equipment inefficiencies. This data is crucial for understanding how environmental conditions may affect the quality and safety of temperature-sensitive products.

A thorough Temperature Mapping study involves placing sensors at various critical points inside cold rooms, refrigerated trucks, or warehouses to monitor how temperatures vary under real-world operating conditions. This helps businesses validate their storage systems and make data-driven decisions.

Why is Temperature Mapping Essential in Cold Chain Logistics?

- Ensures Product Integrity

Even minor fluctuations in temperature can damage high-value products such as vaccines, insulin, meat, or dairy. Temperature Mapping helps ensure that the environmental conditions remain within required ranges to maintain product potency and safety. - Regulatory Compliance

Global health and food safety organizations, such as the World Health Organization (WHO), the Food and Drug Administration (FDA), and local authorities, require cold chain facilities to provide validated temperature control systems. Temperature Mapping studies are a critical part of fulfilling these regulatory standards. - Identifies System Weaknesses

Mapping allows you to detect uneven cooling, faulty equipment, poor airflow, or locations in your facility that are more prone to temperature shifts. Fixing these weaknesses ensures more uniform and reliable cold storage or transport. - Reduces Wastage and Financial Losses

Temperature excursions can lead to spoiled products and financial loss. A detailed Temperature Mapping study can help identify and eliminate these risks, reducing the chances of expensive product recalls or customer complaints. - Audit Readiness and Transparency

Whether it’s an internal audit or an inspection by a regulatory body, Temperature Mapping data provides documented evidence that temperature-sensitive products have been stored and transported under optimal conditions.

How Eximia360 Supports Cold Chain Operators

At Eximia360, our expert team uses state-of-the-art data logging equipment and analysis tools to perform accurate Temperature Mapping studies. We offer customized solutions based on your facility size, product type, and operational needs. Our process includes:

- Initial risk assessment

- Sensor placement strategy

- Real-time temperature monitoring

- Data analysis and visualization

- Detailed compliance-ready reports

- Recommendations for system improvements

Our services are available across Saudi Arabia, especially in Jeddah, Dammam, and Riyadh, where demand for robust cold chain logistics is growing rapidly due to healthcare advancements and the expansion of food distribution networks.

Conclusion

As cold chain logistics becomes increasingly complex and critical, businesses must adopt proactive measures to ensure temperature stability. Temperature Mapping is no longer optional—it is essential for maintaining product quality, complying with global standards, and protecting your bottom line.

With years of expertise in temperature control solutions, Eximia360 stands ready to support your cold chain operation. Visit www.eximia360.com to learn more or to schedule your Temperature Mapping study today.

Invest in data. Protect your products. Trust Eximia360.